3D Printing is a type of additive manufacturing. Things are constructed in trim levels, piled on top of each other at an opportunity.

3D inkjet printers are practically a form of CNC machine. However, they are hardly ever pertained to because they may be complex! Examples of this are marble sculpting and CNC milling (computer system numerical control).

History of 3D Printing

3D Printing has been around for an extended period. Since the 1980s, designers and designers have had access to business 3D printers– these frequent price 10s of countless bucks and often mandate pricey help buy regular upkeep.

The latest surge of interest in 3D printing has happened due to license expiry. Nowadays, you can buy a 3D laser printer for your home for around $1,000 or much less. 3D printing techniques will undoubtedly continue to develop as more licenses end in the future.

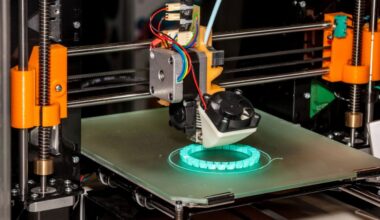

Have a look at this version of the Eiffel Tower. Notice exactly how it becomes the bed relocates down. It is reasonably representative of what 3D color printer styles resemble.

Terminology

Just before digging unfathomable right into 3D Printing, listed below is some popular slang you might run into along the road.

Filament: A component (commonly plastic) created into a long fiber (like a wire). These are utilized through some types of 3D color printers to create items.

Extruder: The part of the device where the product is thawed.

Nozzle: A slight gap from where the dissolved filament is pressed (extruded) away.

Bed: The surface on which a 3D published object is created.

Hot Bed: A print surface that is warmed to offer far better adherence.

Stepper Motor: A solid and accurate motor used to move a printer’s numerous components.

RepRap: An available resource 3D printer action.

G-code: Guidelines for a device describing every motion demanded to make a part. General to 3D Printing.

Slicer: A software application that transforms 3D styles to G-code.

Axis: An endorsement line for action. A 3 axis maker may relocate

X (entrusted to the right), Y (front, back end), as well as Z (up and down).

Carriage: A moving part on which the extruder remains.

What can we do?

Virtually anything! 3D published parts won’t be substituting conventional production procedures for assembly-line production anytime soon. No printer is swiftly enough or even capable of creating the needed high quality where 3D Printing sparkles is in the prototyping and residence manufacturing markets.

Point out the dial on your cleaning machine rests, and the supplier quotes your $30 for a tiny part of plastic plus freight. Why not create your substitute and be up and running within a day, at a fraction of the price? You can efficiently utilize a 3D laser printer at home for even more motivation. Check out these methods.

There is a primary reason the Ford Motor Business has 3D imprinted over 500,000 model car parts. Possessing the capacity to modify a component and publish it once again is a big convenience even though that part takes five hrs to the device, it is still a pretty fast process.

Types of Printer

Once you know what 3D printing is, permit’s look at the different types of equipment. There are two kinds of print: Merged Affirmation Modelling and Stereolithography. These have their assets and also weaknesses. Therefore here are the essentials.

Fused Deposition Modelling

Fused Deposition Modelling, or FDM, is the most basic and preferred approach to printing. The printing component is pushed with a warm cylinder.

This cylinder is intimidated to draw the called form, like piping a message onto a pie. The temperatures vary depending on the component. However, 200C/392F is the average for buyer machines printing in plastic.

Popular models:

- RepRap Prusa I3

- Makerbot Replicator

- Ultimaker 3

It is presently the best popular print. Rates range from $200 up to several many thousand bucks. There is a myriad of different manufacturers and models for FDM makers. They imprint plastic in layers, each property upon the previous, lower level.

Machines begin at the bottom and build upwards. It can point towards the difficulty of making sophisticated shapes or even items without a flat center. Models typically possess lines where each layer has been constructed. If called for, it could be smoothed afterward.

Stereolithography

Stereolithography (SKID ROW) is incredibly various to FDM. It starts with a compartment of unique fluid plastic. A UV laser is driven on top of the material, triggering it to thicken (not the whole great deal, just a tiny layer).

Much like FDM, each level is drawn as well as healed successively. These machines operate from scratch down, pulling the things out of the fluid.

Models generated utilizing SLA are incredibly hassle-free, along with an extremely high resolution. They are quicker to print than FDM devices. Nonetheless, they are less usual, much more expensive, and rely on pricey material.

Popular models:

- Formlabs Form 2

- 3D Systems ProJet 1200

- XYZ Printing Nobel 1.0

Cartesian

Considerably like a traditional inkjet or laser device inkjet printer, cartesian devices are relatively straightforward. Listed here’s what a cartesian laser printer searches like:

Delta

Delta machines put on hold the extruder from three branches in a triangular agreement. These machines are created to print parts quickly!

They are perfect for high, slim versions. They are only somewhat even more complex and also pricey than standard cartesian devices, so they embody an outstanding alternate option.

Final Thoughts:

3D printing is an advanced level of technology that is useful in so many ways. It can make almost anything. We have discussed its importance and its uses extensively in this post.

3D published parts won’t be substituting conventional production procedures for assembly-line production anytime soon. No printer is swiftly enough or even capable of creating the needed high quality where 3D Printing sparkles is in the prototyping and residence manufacturing markets.